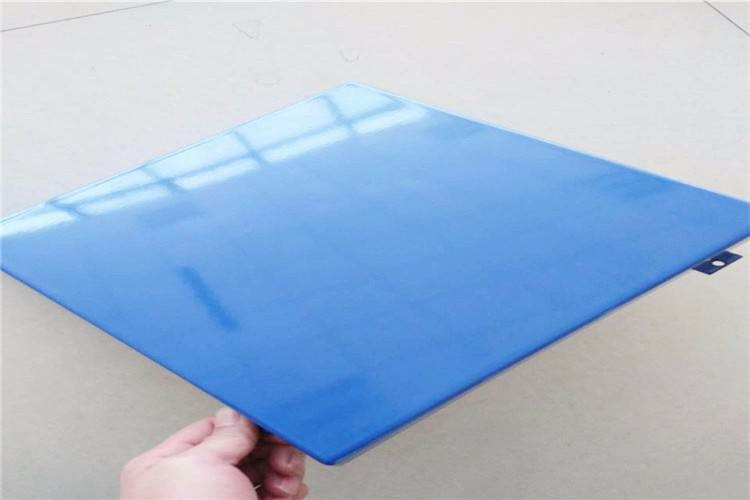

The ultra corrosion resistant powder color coated steel plate has the high coating compactness, high corrosion resistance, good insulation and energy efficiency. It also have the good edge coating. The traditional color coated steel plat, adopts the roller coating method, which results in almost no coating in the edge of base metal. However, the powder color coated steel plate adopts the electrostatic coating way construction, edge ministries have a lot of paint. However, the powder color coated steel plate adopts the static electricity coating method, so it can equably paint the metal, even the edge part. Therefore, powder painted can effectively protect the metal from corrosion, further extending the service life of the metal.

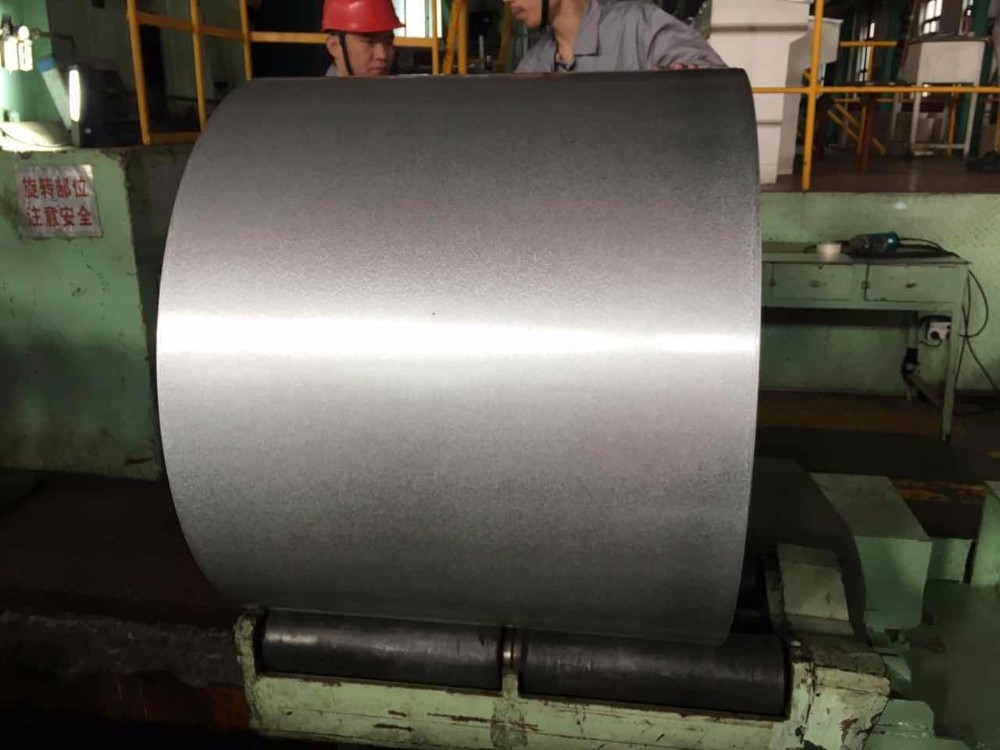

Galvalume steel is also called Aluminum-Zinc Alloy Coated Steel,aluminized zinc steel(aluzinc steel),SGLC,The galvalume metal is composed of 55% aluminium, 43.4% zinc and 1.6% silicon solidified at 600 ~C. Its whole structure consists of aluminium-iron-silicon-zinc, forming a compact quaternary crystal alloy.

High-performance Powder Coated Steel Sheets

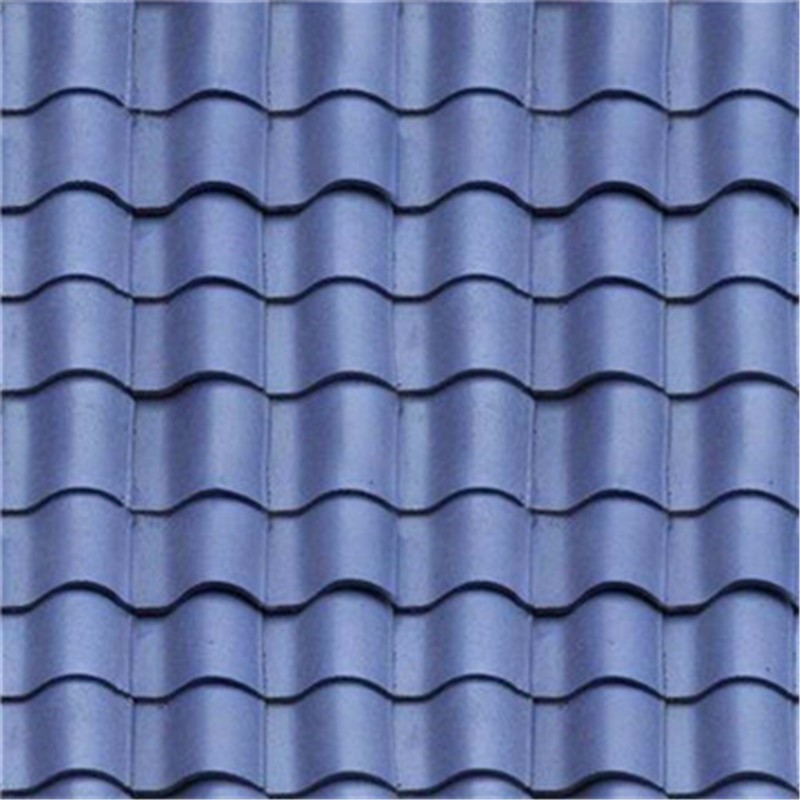

The product obtained by coating an organic coating on a hot-dip galvanized steel sheet, which is a hot-dip galvanized color-coated plate. In addition to the protective effect of zinc, the hot-dip galvanized color-coated plate also protects against rust and has a longer service life than hot-dip galvanized sheet. The zinc content of the hot-dip galvanized substrate is generally 180 g/m2 (double-sided), and the galvanizing amount of the hot-dip galvanized substrate for external use is up to 275 g/m2.

High Tensile corrugated sheet/ PPGI Prepainted Galvanized Steel Coil for Construction/Roofing Material for tiny house

Enamel Coated Steel Plate Enamelled steel is a material with exceptional properties and has many applications in various aspects of everyday life. In the home, enamelled steel is used in the kitchen for worktops and casings for domestic appliances. Enamelled steel also has important applications in industry, even in the most corrosive atmospheres, e.g. in the chemical and agro-food industries. Finally, the use of enamelled steel is a first-rate solution in the con- struction industry for cladding buildings or for interior decoration, as it successfully combines a rigid steel substrate with an enamel coating. The result is an end product that is aesthetically pleasing, durable and easy to clean. Enamelled steel can also be an appropriate option for lining tunnels, as it ensures they are easier and cheaper to clean and improves fire resistence.

The product obtained by coating an organic coating on a hot-dip galvanized steel sheet, which is a hot-dip galvanized color-coated plate. In addition to the protective effect of zinc, the hot-dip galvanized color-coated plate also protects against rust and has a longer service life than hot-dip galvanized sheet. The zinc content of the hot-dip galvanized substrate is generally 180 g/m2 (double-sided), and the galvanizing amount of the hot-dip galvanized substrate for external use is up to 275 g/m2.